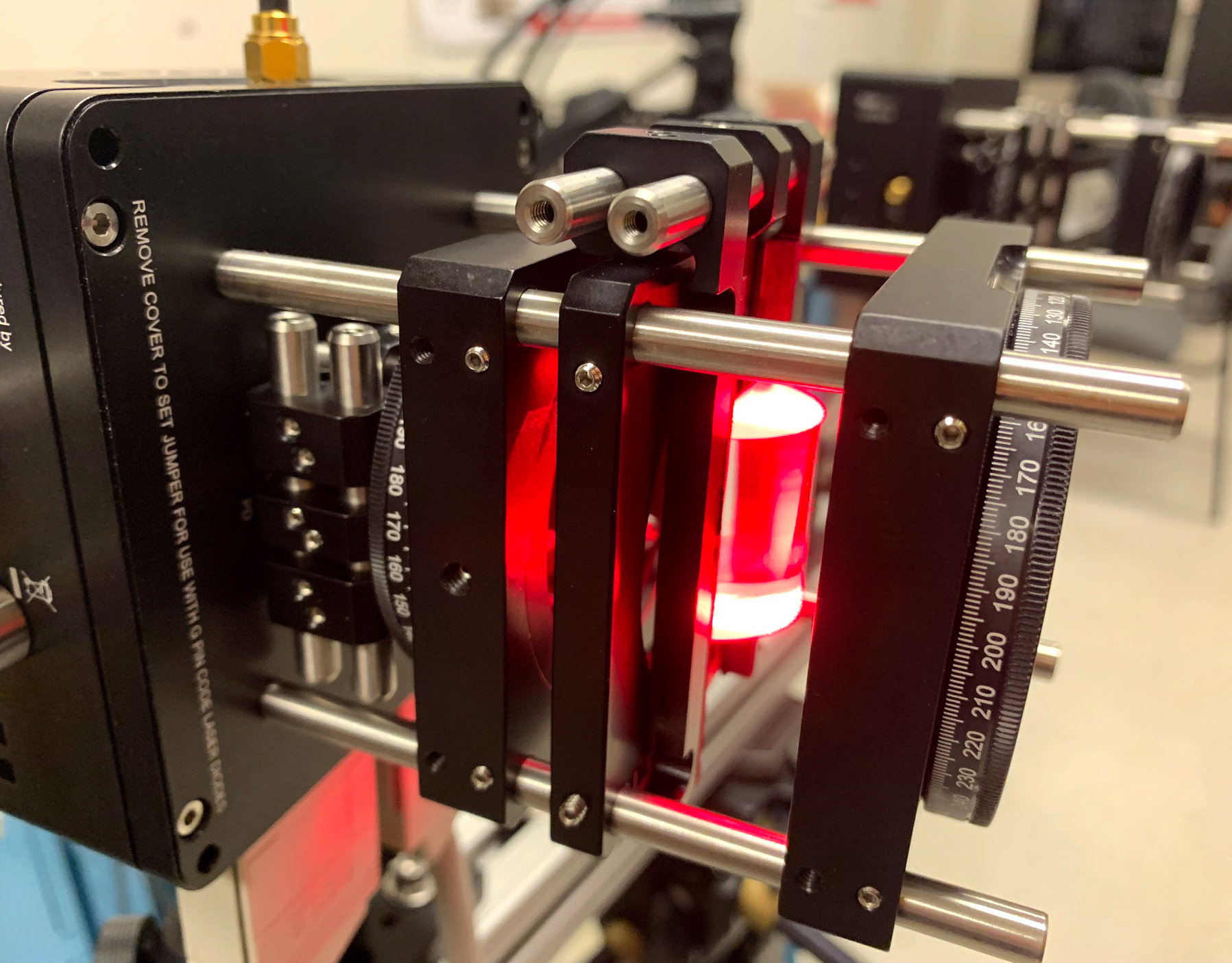

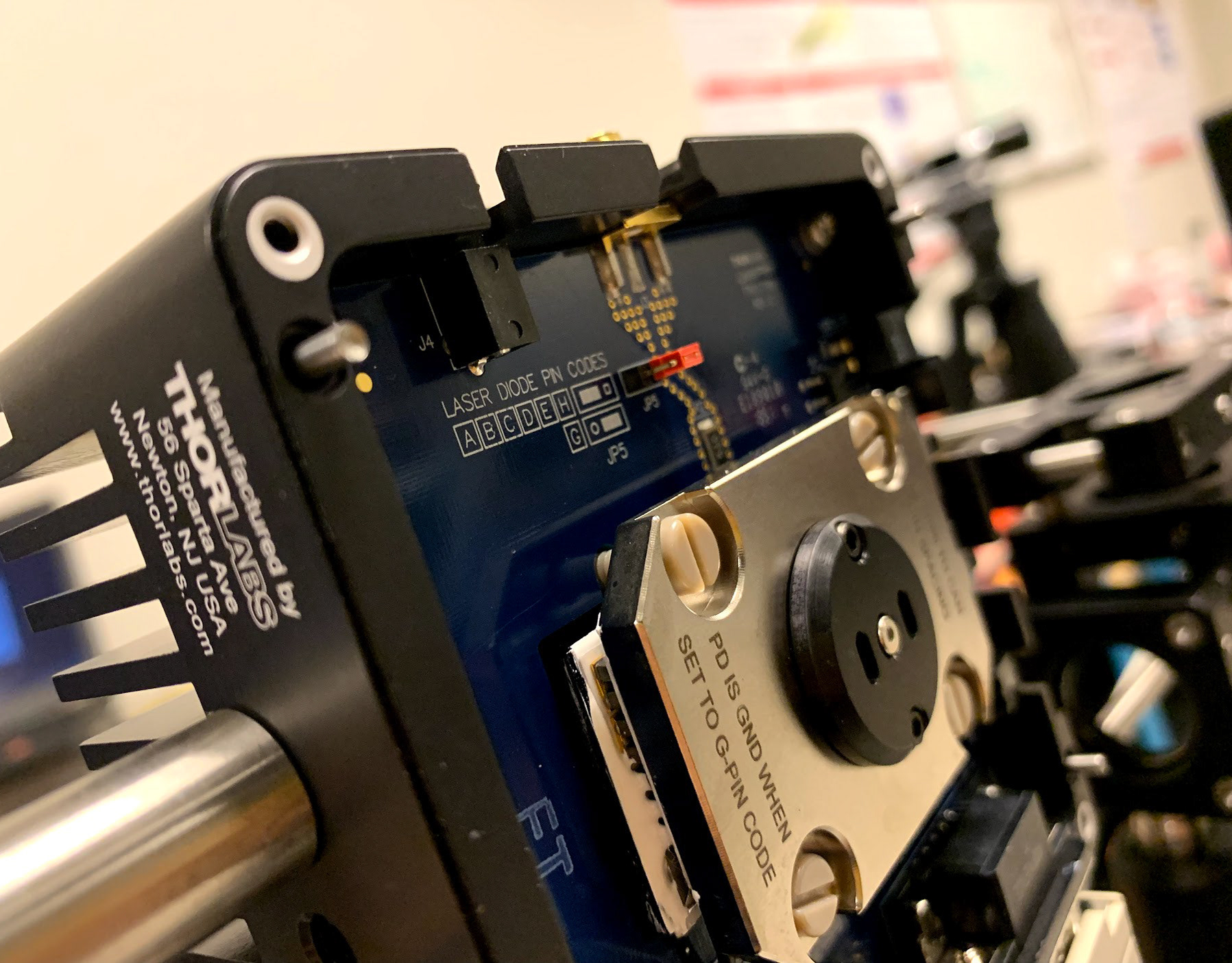

- Integrated non-contact laser ultrasonic (UT) systems for damage inspection

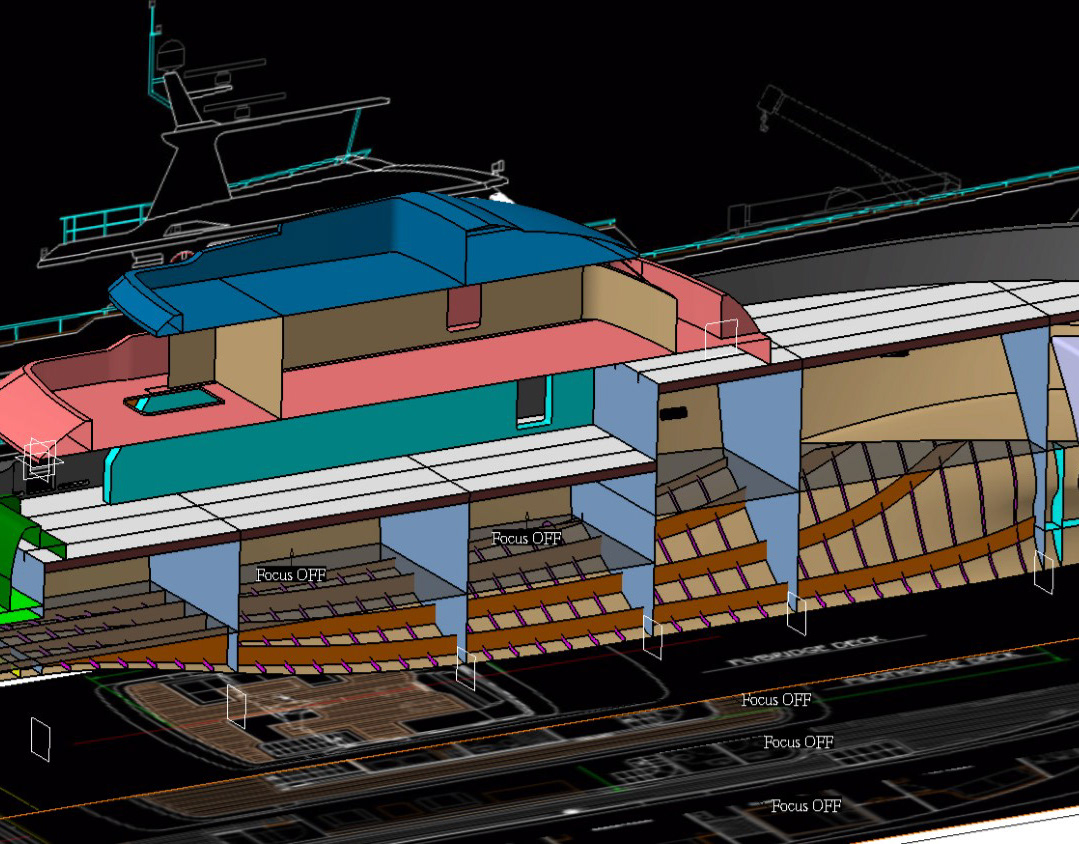

- Modeled planar and cylindrical waveguide on elastic and composite structure

- Characterized wave propagation on fiber optics & laser ultrasound for damage inspection

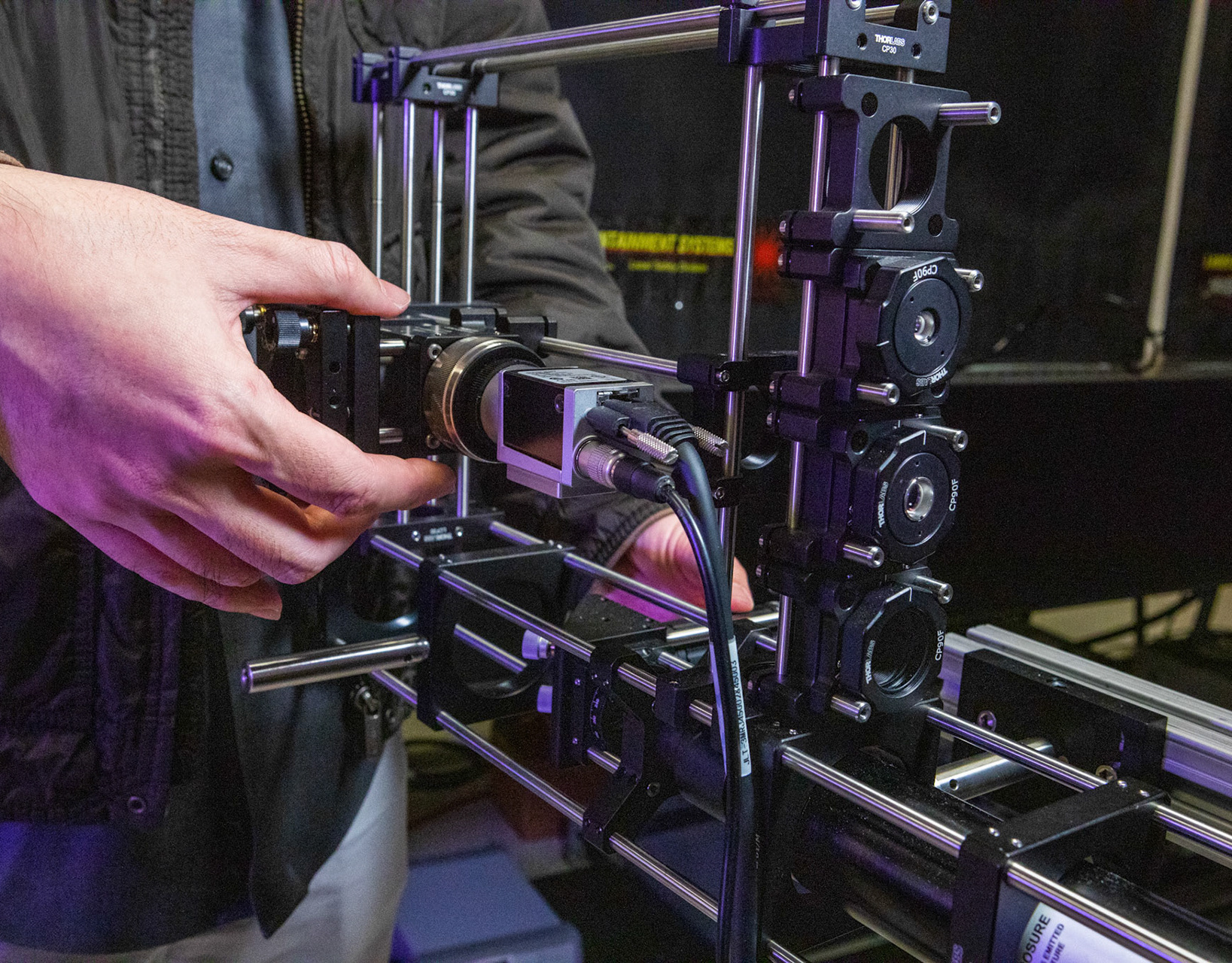

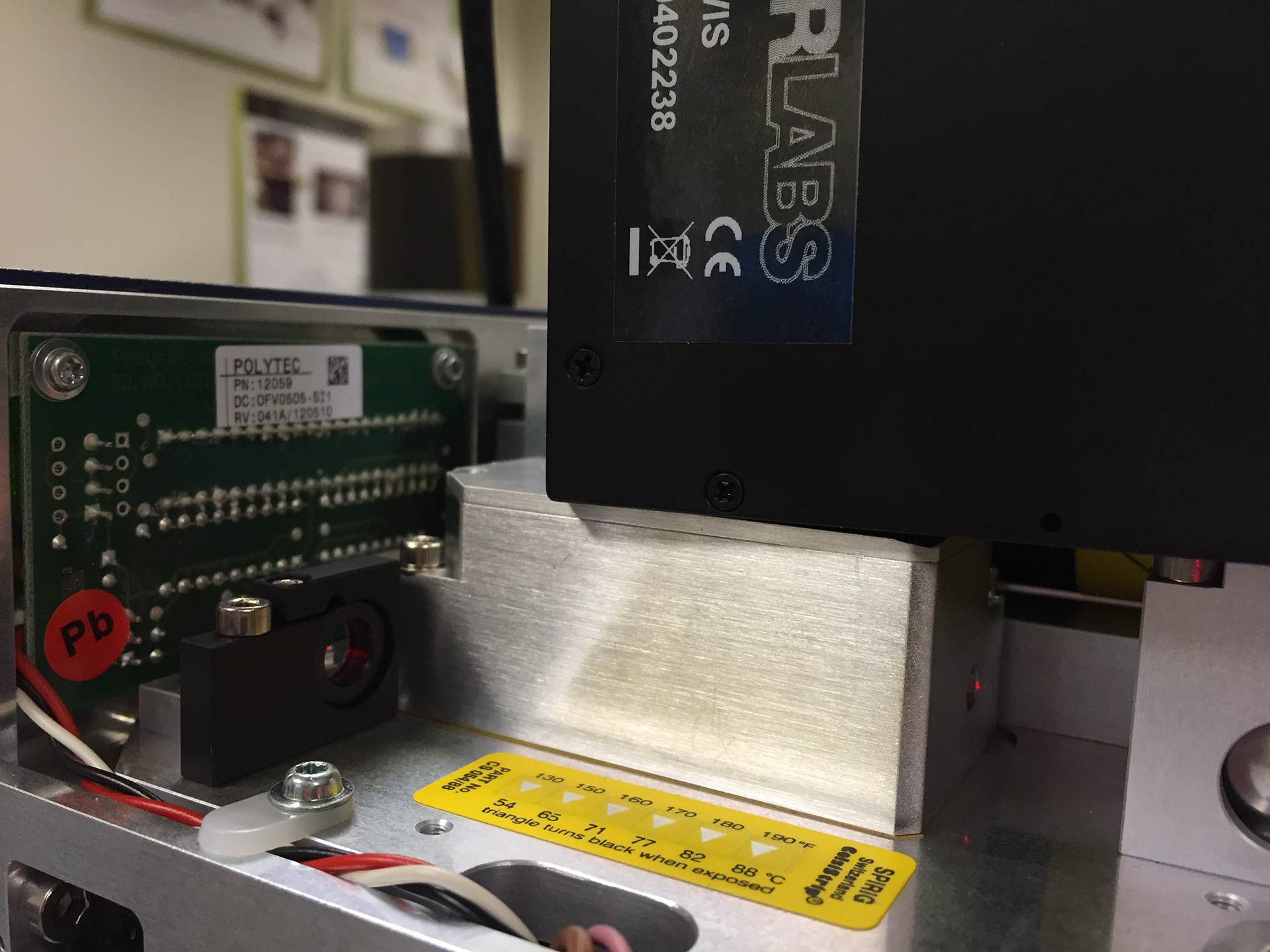

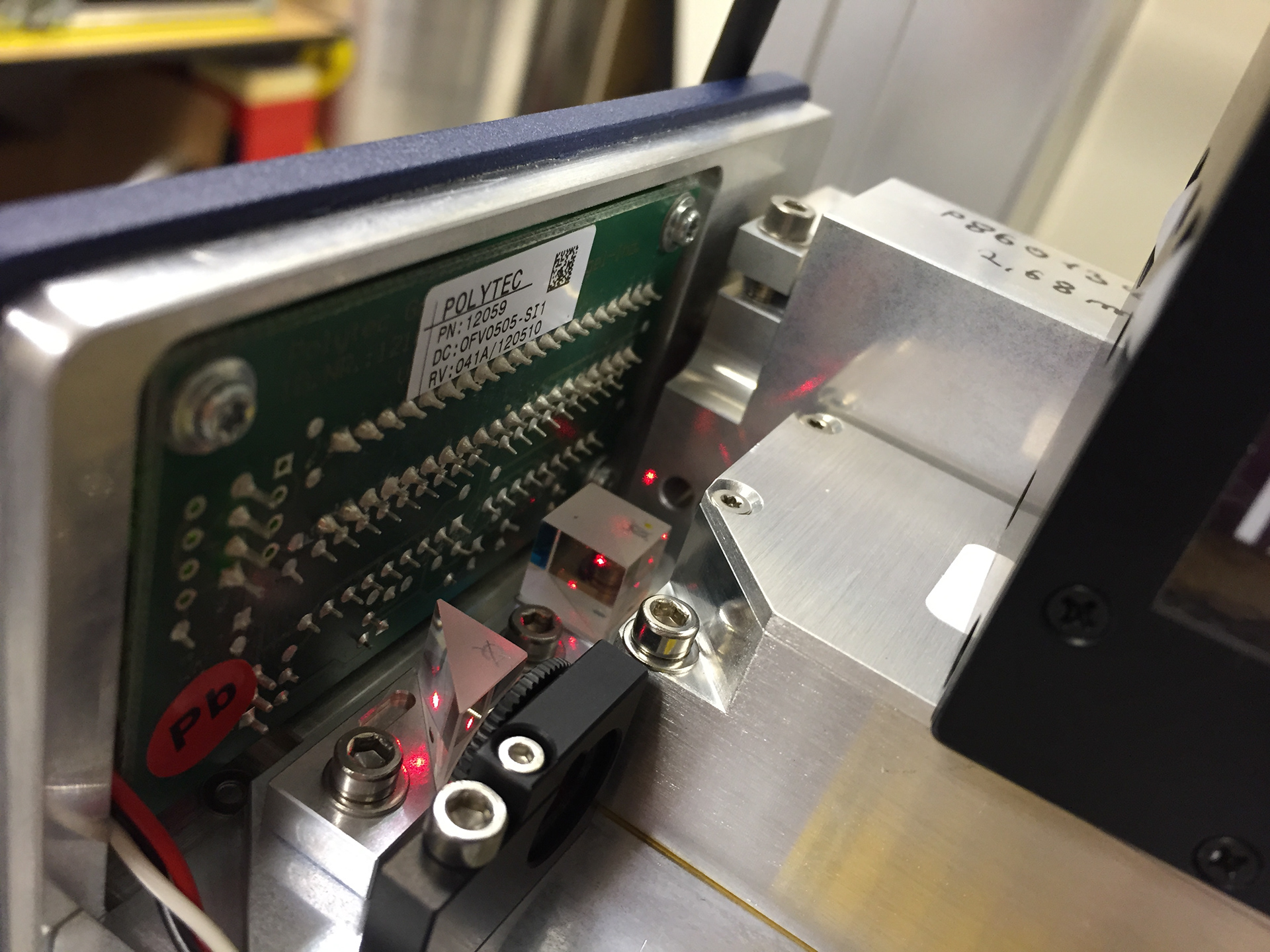

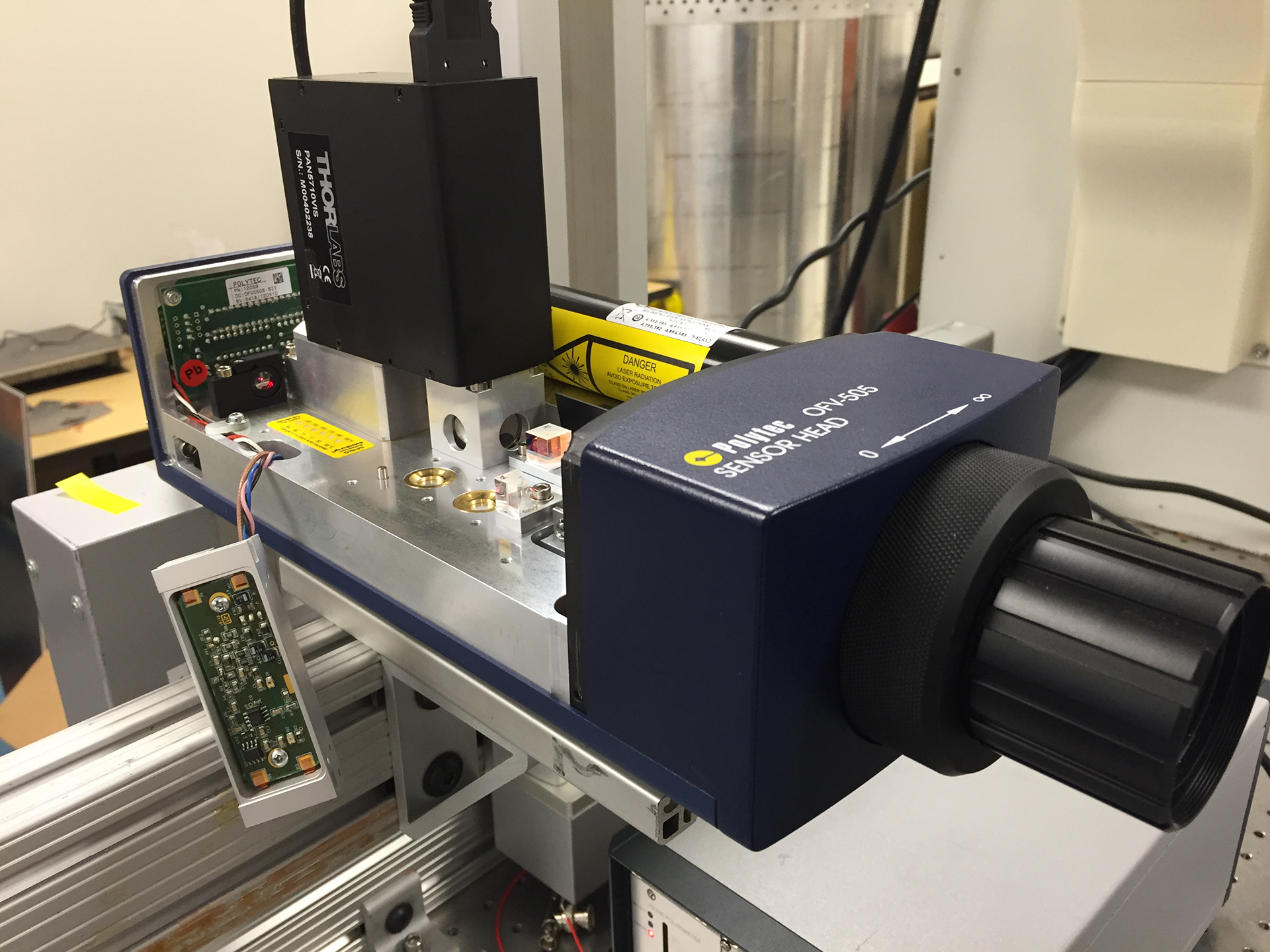

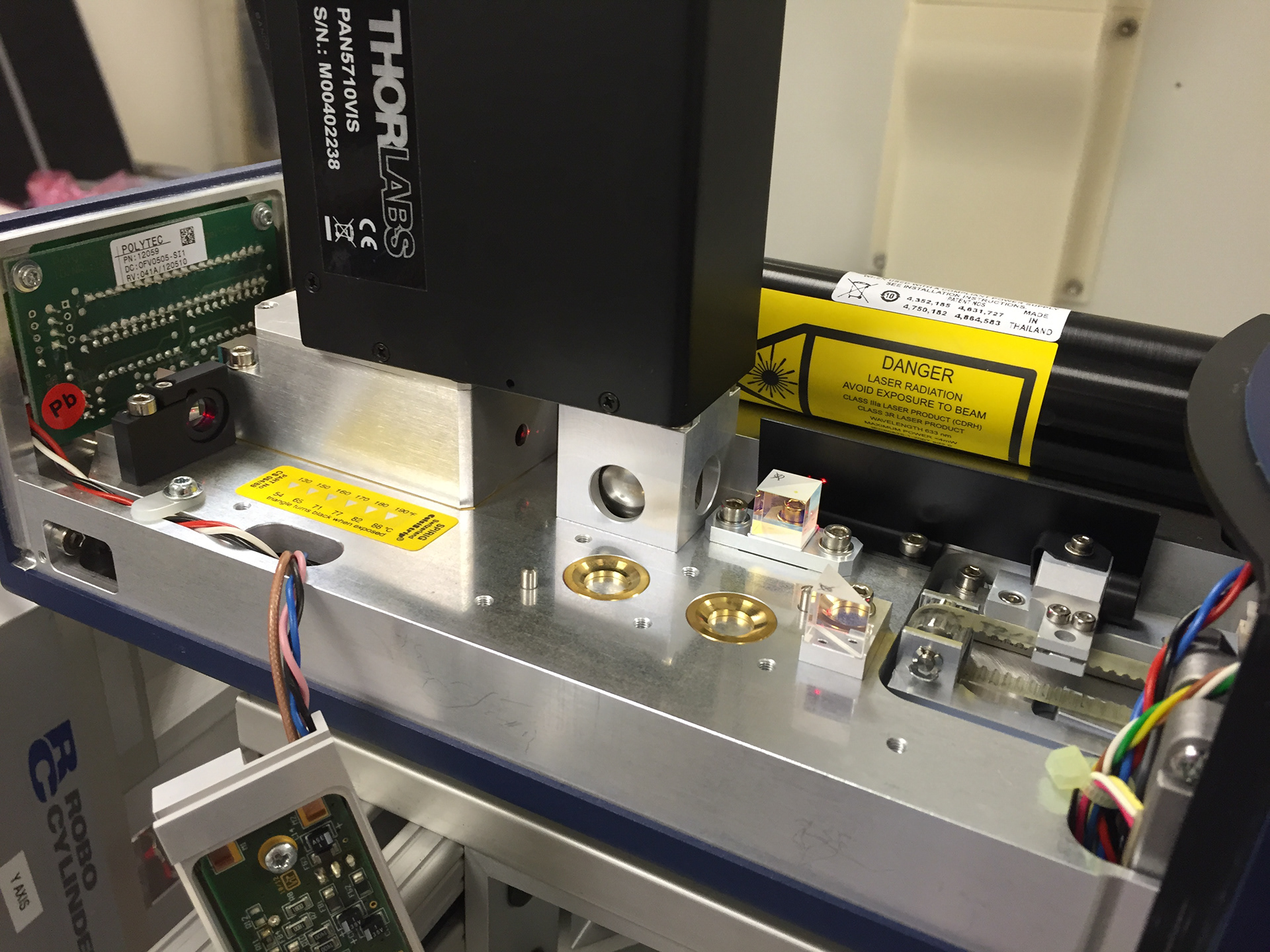

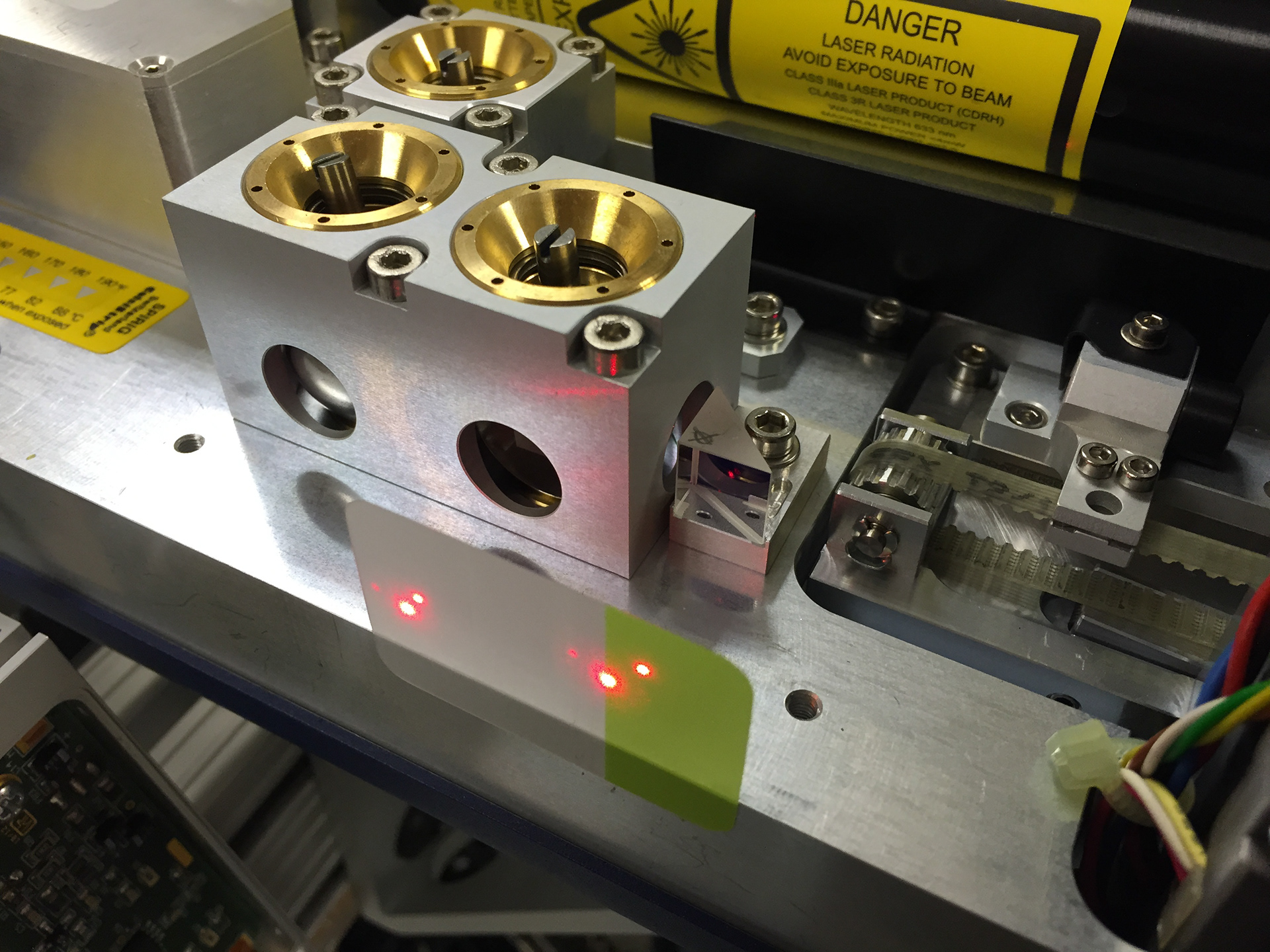

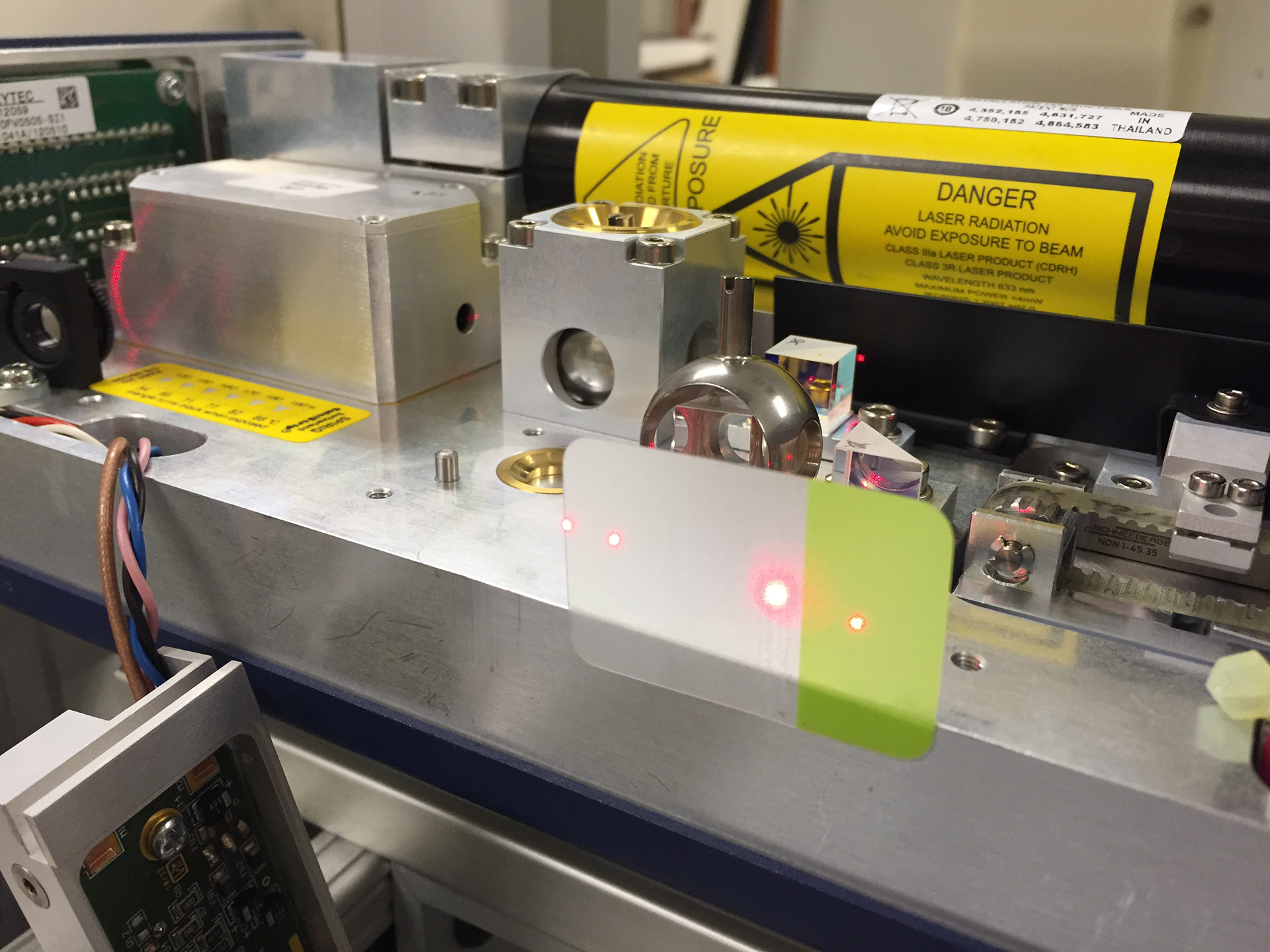

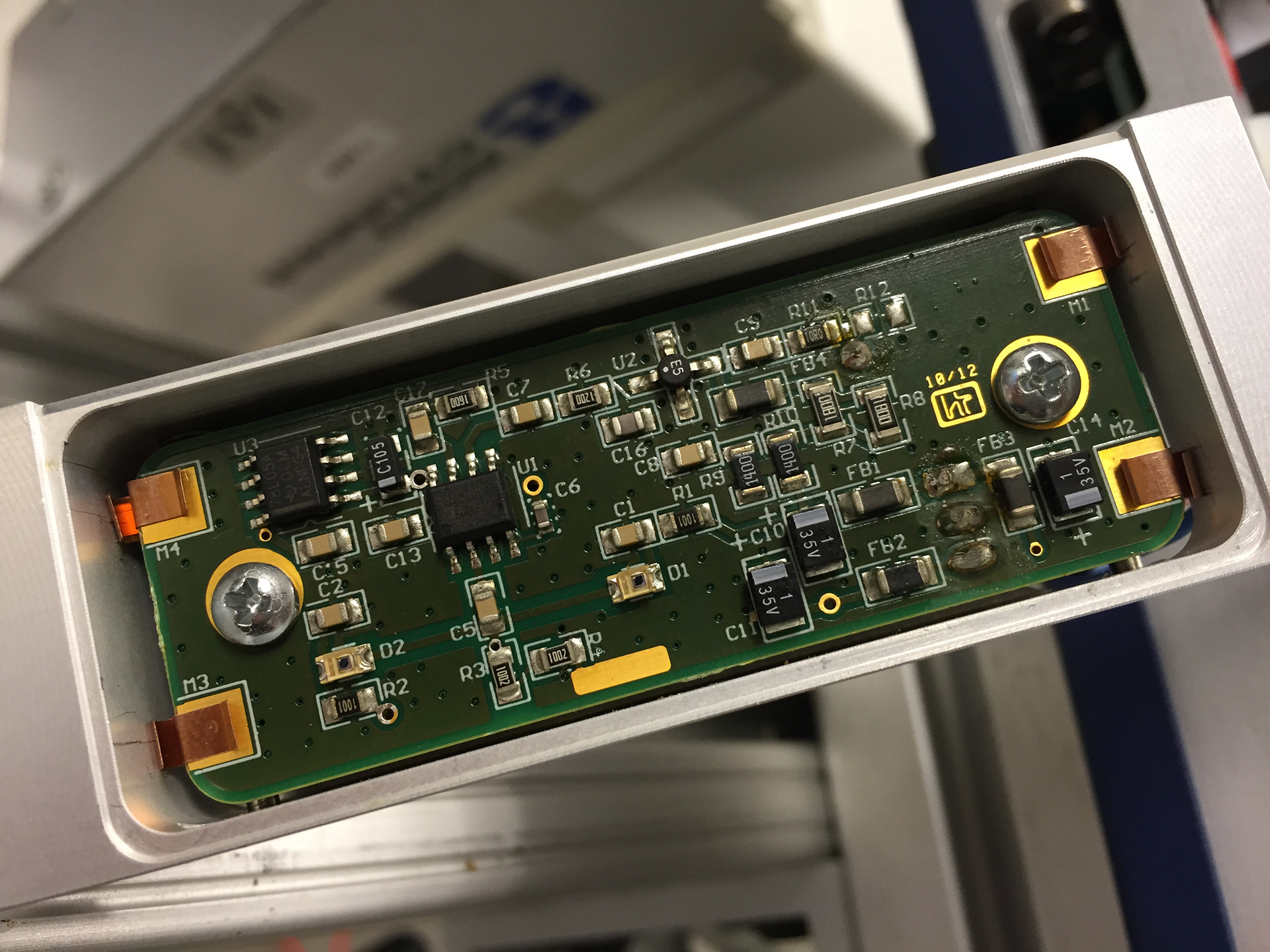

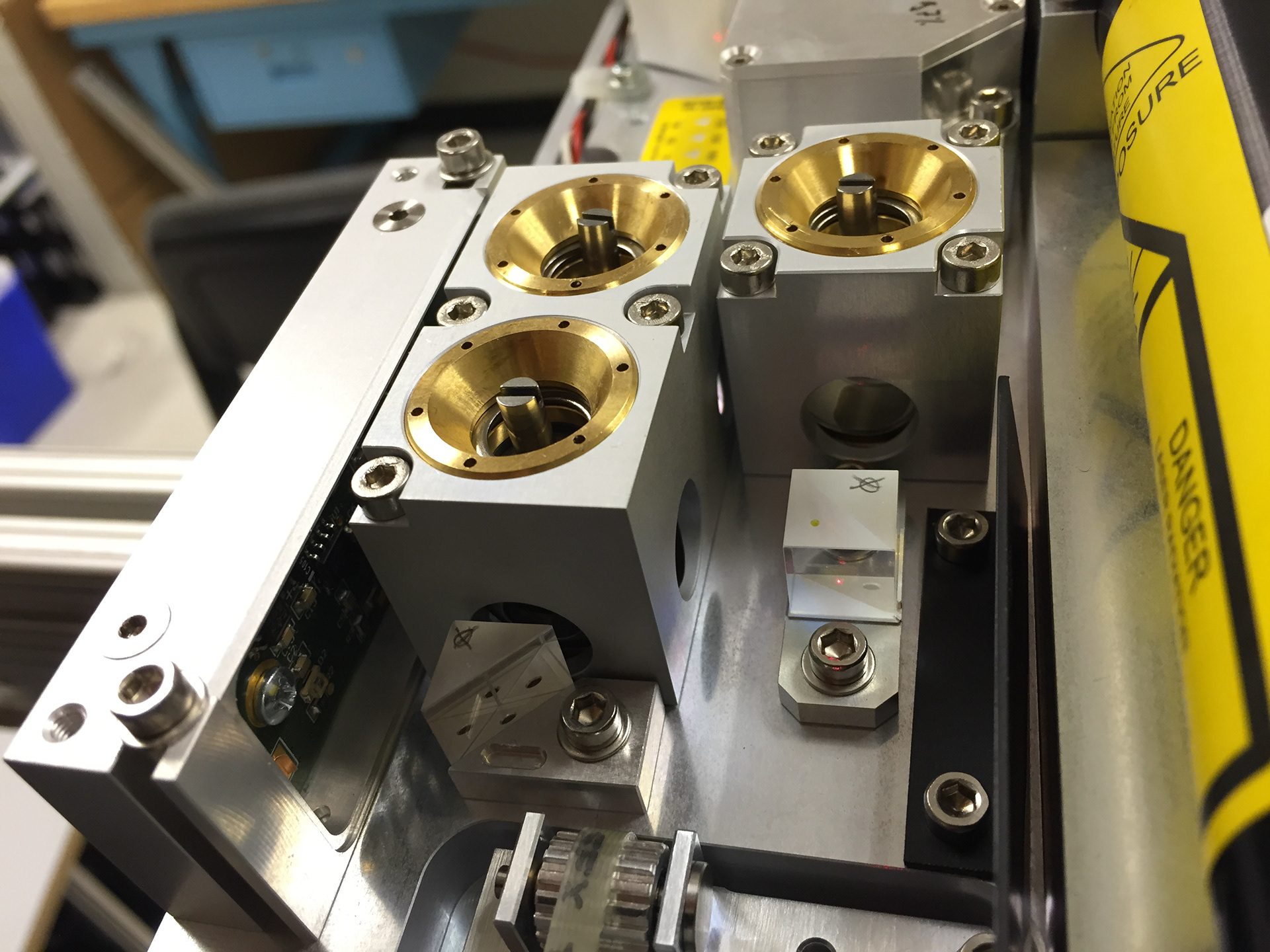

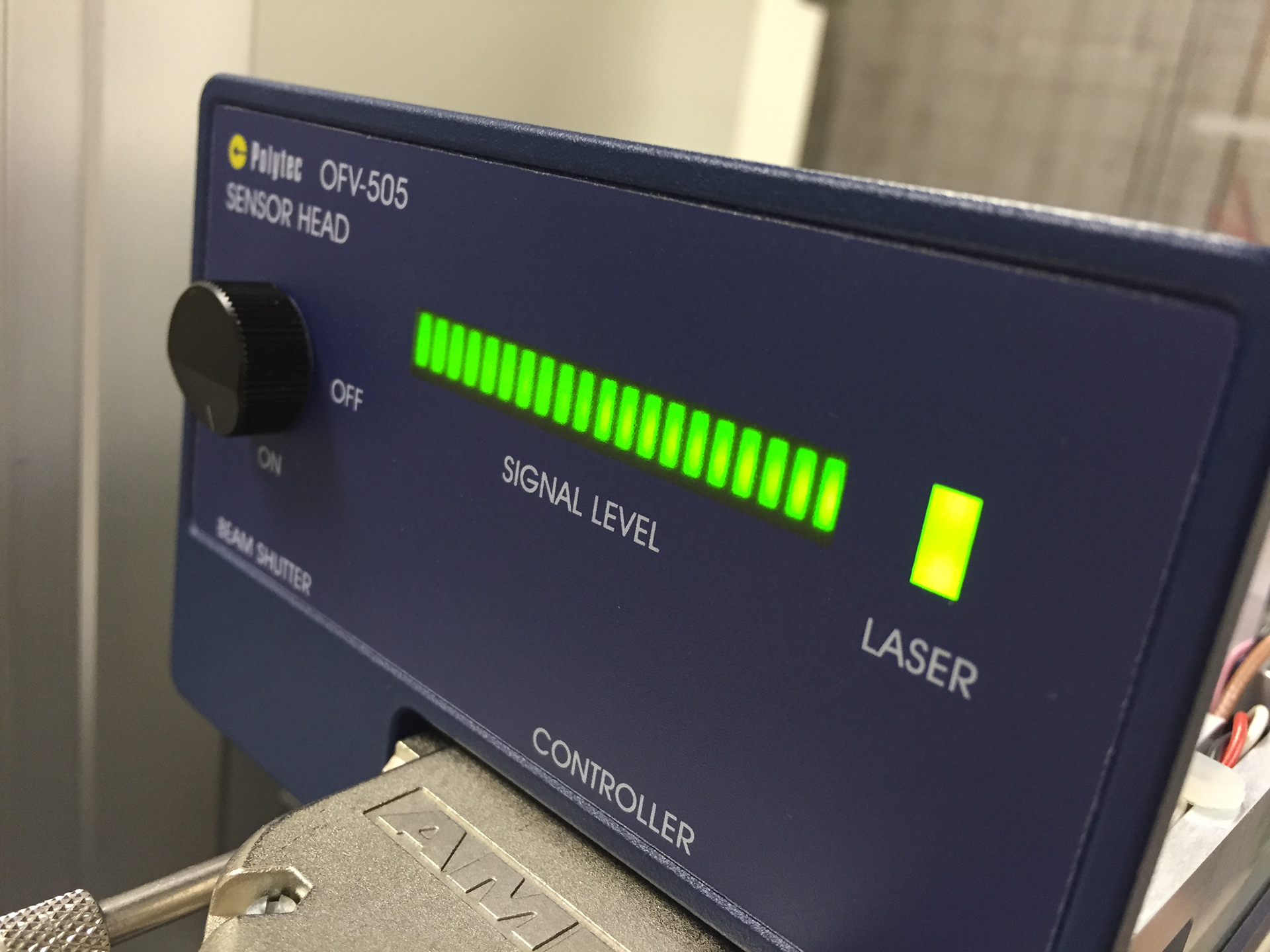

Laser Doppler vibrometer is a key non-contact tool in measuring the surface vibration of a remote target. The vibrometer enables the measurement of wideband response (i.e., the vibration frequencies from DC up to 24 MHz and vibrational velocities of 0.01 μm/s up to 20 m/s). It is widely used to detect any material defects by measuring surface acoustic wave propagation generated by a pump laser. A defect in the material will disturb the propagation of the surface waves.

By scanning the laser beams either from the pump laser or the probe laser inside the laser Doppler vibrometer across the target surface, the defect locations and region can be identified. Since it is used to measure very minute surface wave disturbance, the vibrometer itself must be very rigid. Any vibration on the vibrometer itself will unavoidably introduce errors and compromise the accuracy.

All rights reserved to

- Smart Structures and Materials Lab, Mechanical and Aerospace Engineering, North Carolina State University

- Integrated Structural Health Management Lab, National Institute of Aerospace

- and all the participated members.

- Smart Structures and Materials Lab, Mechanical and Aerospace Engineering, North Carolina State University

- Integrated Structural Health Management Lab, National Institute of Aerospace

- and all the participated members.